Understanding the Aluminum Motor Housing Manufacturing Process

2025-11-13 17:31Understanding the Aluminum Motor Housing Manufacturing Process

1. Choosing the Right Material

The process begins with aluminum alloy 6063, a material commonly used for extrusion due to its balanced strength, smooth surface quality, and formability. Before processing, the billets go through standard checks such as composition and density testing to ensure consistency.

Key considerations at this stage include:

Material stability during extrusion and machining

Surface quality for later finishing

Compatibility with the motor’s thermal and structural requirements

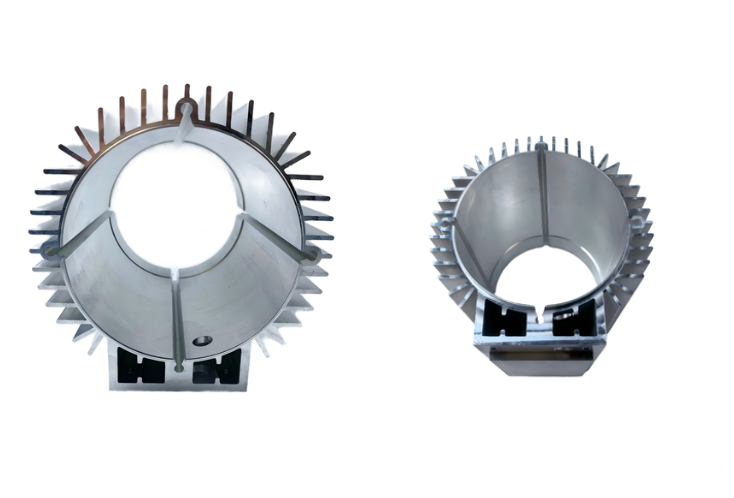

Heating the billet and pressing it through a precision die forms the base profile that will later be machined into shape.

2. Shaping Through CNC Machining

Once the extruded profile is prepared, CNC machining handles the more detailed work. This step refines the housing, so it meets the mechanical and assembly needs of different motor types.

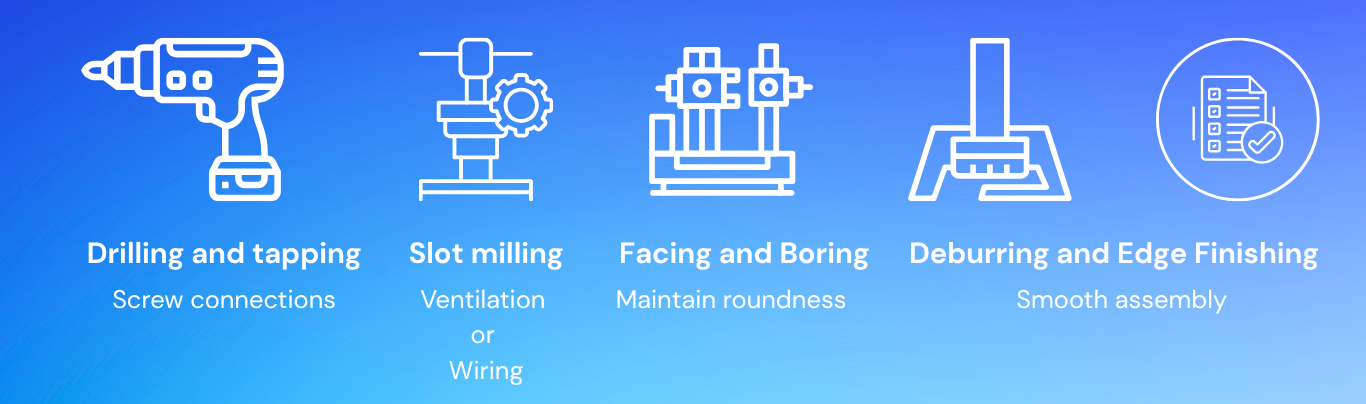

Typical machining operations include:

3. Surface Treatment for Protection

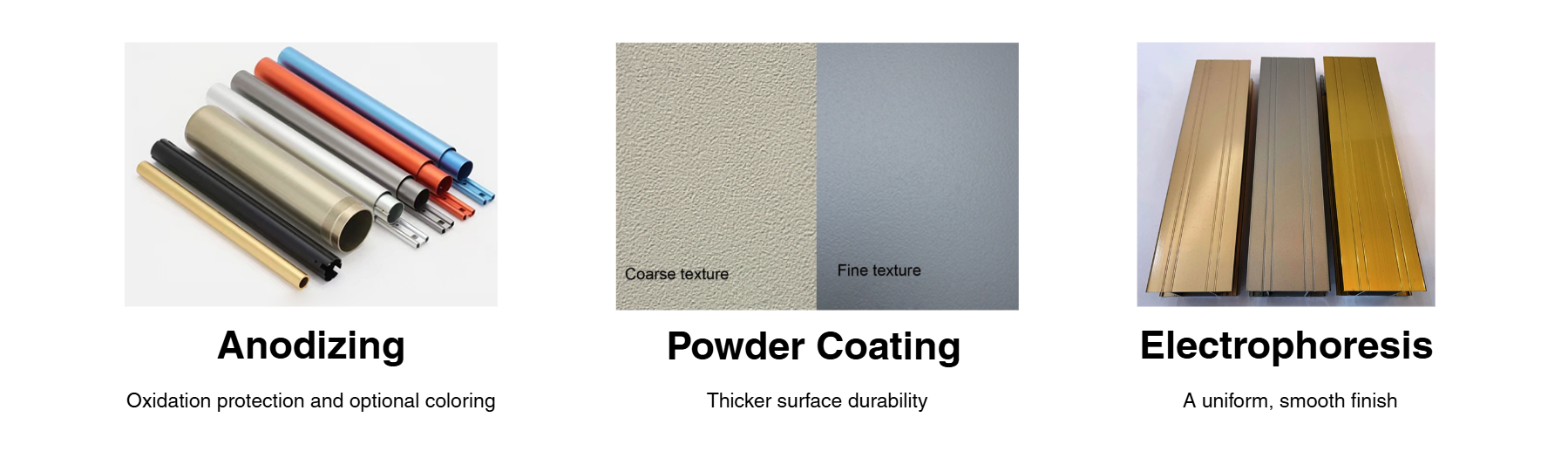

After machining, the housings receive surface treatment to improve resistance to corrosion and environmental wear. These finishing processes also help maintain temperature stability and surface cleanliness.

Common treatment options include:

Each method serves different usage environments, from humid conditions to high-friction industrial setups.

4. Inspection & Assembly

Before final assembly, the components are measured for:

Dimensional accuracy

Concentricity and alignment

Surface smoothness and coating consistency

Only after passing these checks are additional parts installed, such as mounting brackets or bearing seats. This ensures the housing fits properly in its intended motor system.

5. Use Across Various Industries

Aluminum motor housings are used in a wide range of applications, including:

Their lightweight structure, good heat conduction, and structural stability make them suitable for equipment that runs continuously or under variable load conditions.

A Practical, Process-Driven Component

From raw material to finishing, the manufacturing of an aluminum motor housing is less about a single process and more about how each step affects the next. Consistent extrusion, accurate machining, and appropriate surface treatment allow the final component to perform reliably in different working environments. This combination of controlled steps is what supports the long-term performance of modern motor systems.