- Home

- >

- News

- >

- Special Tubes

- >

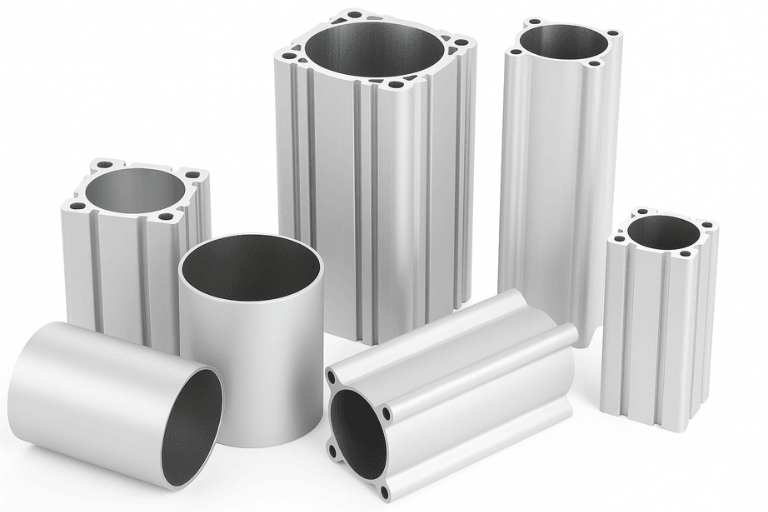

Special Tubes

2025-11-06 14:33Special Tubes

Custom Solutions for Demanding Applications

What Are Special Tubes?

Special tubes are customized solutions designed for applications that require specific characteristics such as higher strength, precise tolerances, or resistance to extreme conditions. Unlike standard tubes, special tubes are manufactured using advanced techniques and materials to meet the most demanding industry requirements.

Types of Special Tubes

Heat Sink Tubes

These tubes are used in electronics and automotive applications to efficiently dissipate heat, ensuring that devices or systems do not overheat.CNC Machined Tubes

Precision-machined tubes made using CNC technology ensure high accuracy, perfect for applications that need specific dimensions and high tolerances.Aluminum Tubes for Batteries

Custom-designed aluminum tubes are used to encase lithium-ion batteries, providing safety and performance for industries like electric vehicles and consumer electronics.

Why Choose Special Tubes?

Custom Design

Special tubes can be made to your exact specifications in terms of size, shape, material, and finish, ensuring the best fit for your unique requirements.Enhanced Durability:

Made from high-quality materials such as titanium alloys, stainless steel, or specialized aluminum grades, special tubes offer enhanced strength, corrosion resistance, and longevity.Precision Engineering

With technologies like CNC machining and laser cutting, special tubes are designed with extremely tight tolerances, making them ideal for industries where accuracy is critical.

Applications in Various Industries

Automotive

Special tubes are used for high-performance applications such as cooling systems, brake lines, and battery casings in electric vehicles.Electronics

In electronics, special tubes serve as heat sinks to manage the heat generated by devices like computers, smartphones, and power systems.Medical

In the medical field, special tubes are used for equipment such as dialysis machines, surgical tools, and life-support systems, where precision and reliability are paramount.

Manufacturing and Customization

Our manufacturing process for special tubes includes extrusion, CNC machining, and anodizing to produce high-precision, custom-designed tubes. We work closely with our clients to tailor every aspect of the tube, from material selection to size and finish, ensuring the best solution for your needs.

Special tubes offer custom-made solutions that can meet the unique demands of your industry. With materials that provide superior strength and durability, along with precision manufacturing techniques, special tubes are ideal for applications that require the best performance. Contact us today for more information on how our special tubes can be tailored to fit your business needs.