- Home

- >

News

As we bid farewell to 2024 and step into 2025, we want to take a moment to express our heartfelt gratitude to all our clients, partners, and team members who have been part of this incredible journey.

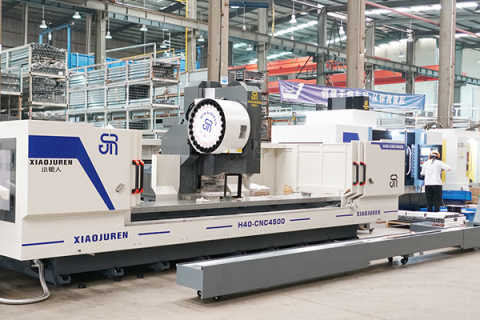

There are four methods for finished aluminum alloy processing: 1. Cutting in aluminum alloy processing. Typically, the standard length of an aluminum profile is 6.02 meters. However, in actual production, various combinations of aluminum alloy lengths are required. Therefore, it needs to be cut according to specific requirements to ensure the cutting length and precision. 2. Punching in aluminum alloy processing. Industrial aluminum alloy installation usually involves the combination of multiple aluminum profiles and fittings of different specifications. Connection components require pre-embedded holes, which need to be punched according to the design requirements using specialized punching machines. 3. Tapping in aluminum alloy processing. Industrial aluminum profiles, fittings, and connection components often require the use of bolts, nuts, and screws, which need to be tapped. 4. Milling slots in aluminum alloy processing. To facilitate the assembly of other accessories in the later stages, it is often necessary to mill slots on the surface of the aluminum alloy, ensuring the efficient installation of other accessories.

Our general manager and project manager give a warm welcome and arranged a meticulous reception work for our customers. accompanied by the main person in charge of the department, our customers visited the company's production workshop, checking the on-site test operation, equipment. the company leadership makes detailed answers to our customers' various questions during the visit.Our customers are very impressive by our rich professional knowledge and the ability to work.